Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

Plug & Seal

Tube Seals - Connector Sealing Plugs - Creating Tight Connections

Quick-Fit Plug Connections for Housings, Pipe Ends and Assemblies

Plug & Seal connectors are pipe sections that are rubberized on their exterior surfaces, with two sealing beads and shock absorbers. They are used to create a tight, lasting connection between housings, pipes and Assemblings for the reliable transport of fluids.

Connecting Components Quickly, Reliably and Tightly

Freudenberg Sealing Technologies developed Plug & Seal connectors to establish a tight connection between two housings, pipes and assemblies – for the reliable transport of fluids such as oil, water or air. Besides the standard design, rubberized pipe sections with two sealing beads and shock dampers are available with interior/exterior sealing, plus additional functions, and as an individualized customer solution.

The advantages of Plug & Seal connectors are many and varied. The main benefit is that they can replace other incomplete components – including cast-iron pipes with machined grooves, flanged aluminum pipes with two mounted O-rings, hoses with hose clamps, and flat and O-ring seals.

Other Advantages at a Glance

Quickly installable Plug & Seal connectors

-

combine multiple functions in a single component

-

compensate for eccentricities and allow greater tolerances during installation

-

provide an acoustic and mechanical decoupling

-

seal reliably even at high pressures

-

allow simple, secure and cost-effective fitting

-

reduce logistics expenses

-

minimize maintenance expenses through significantly improved durability

-

offer clear benefits stemming from low overall cost

Our Products in Detail

Plug & Seal: Sealing Internally and Externally

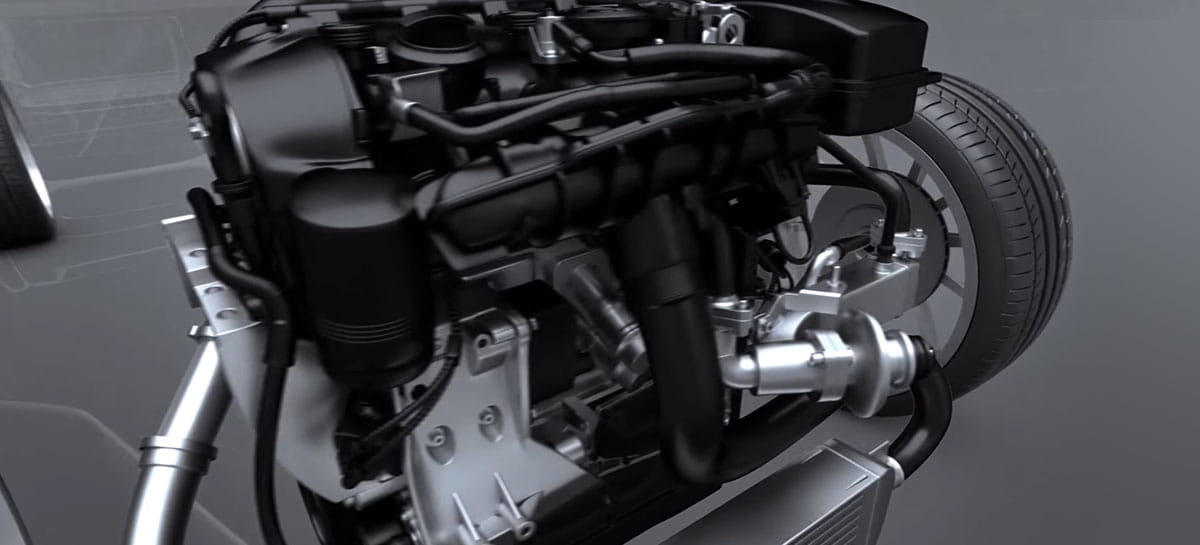

Individually adjusted, internally and externally sealing Plug & Seal connectors can be used to good effect in the following applications:

- Sealing a long or coiled fluid feed in the engine cooling circuit, through a line with an interior/exterior sealing Plug & Seal at both ends

- Sealing and decoupling between the coolant manifold and the cylinder head in a stationary diesel engine with an interior/exterior sealing Plug & Seal product (see figure)

Plug & Seal for Efficient Installation

In practice, one aspect is very important: whether the fitting of seals and components is easy, safe and efficient to execute. These objectives can be achieved with Plug & Seal connectors:

- Plug & Seal fix themselves in the installation space

- Simplified overhead fitting

- Multiple installation of all seal connections in one work sequence

To further automate the multiple installation of Plug & Seal products, it is possible to establish a chain of interlinked Plug & Seal seals (see figure).

Plug & Seal With Additional Functionality

Plug & Seal connectors can be configured innovatively and individually to handle different functions. One example of a Plug & Seal with extra functionality is the fluid feed in the oil cooler of an internal combustion engine. The Plug & Seal takes over the following functions:

- Tight fluid feed between the oil cooler and engine block

- Compensation for misalignment

- Guaranteeing a minimal oil level in the oil cooler

- Protection of pipe connections in an abrasive airflow through the use of an elastomer coating

Related Topics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new