Aerospace

Sealing Innovations in Aerospace: Redefining Boundaries for Tomorrow's Skies

Empowering Aerospace Innovation

Aerospace technology propels progress by conquering challenges posed by aggressive fluids, high pressures, extreme temperatures, and the critical need for thermal protection. These sealing innovations revolutionize aviation by optimizing weight, reducing friction, cutting costs, and mitigating environmental impact—ushering in an era of extended distances, accelerated speeds, and heightened cost efficiency.

At Freudenberg Sealing Technologies, we stand at the forefront as the global leader in delivering premium technical sealing and elastomer solutions. Trusted across industries, including aerospace, our expertise spans over 175 years of engineering and material mastery. Serving as steadfast development and service partners, our commitment remains unwavering centered on surpassing customer expectations and fulfilling diverse needs.

Our Customer-Centric Approach to Sealing in Aerospace

-

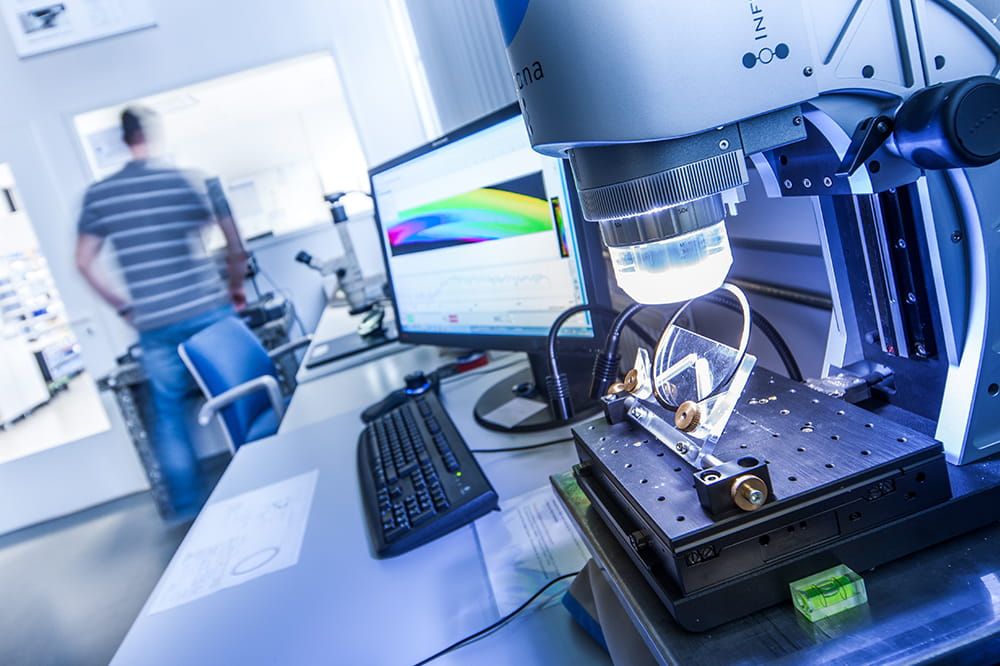

Materials

Pioneering proprietary formulations, meticulously crafted in-house, exceed customer requirements. -

Design

Globally shared innovative sealing concepts backed by rigorous FEA, testing, and extensive field experience. -

Quality

From AS9100 to nadcap, our aerospace facilities ensure precision and zero escapes, maintaining original product intentions. -

Delivery

Reduced lead times coupled with 100% on-time supply guarantee, surpassing industry standards. -

Value = Function/Cost

Providing customers with the optimal solution, maximizing value proposition.

Aerospace Sealing Product Range

Elevating Aviation Standards

Our O-rings excel in aircraft functions, delivering Six Sigma quality and exceptional resistance to temperature and chemicals. Available in AS568, BS1806, and metric sizes, our exclusive elastomer formulations promise versatility across diverse applications, meeting industry demands with unparalleled performance.

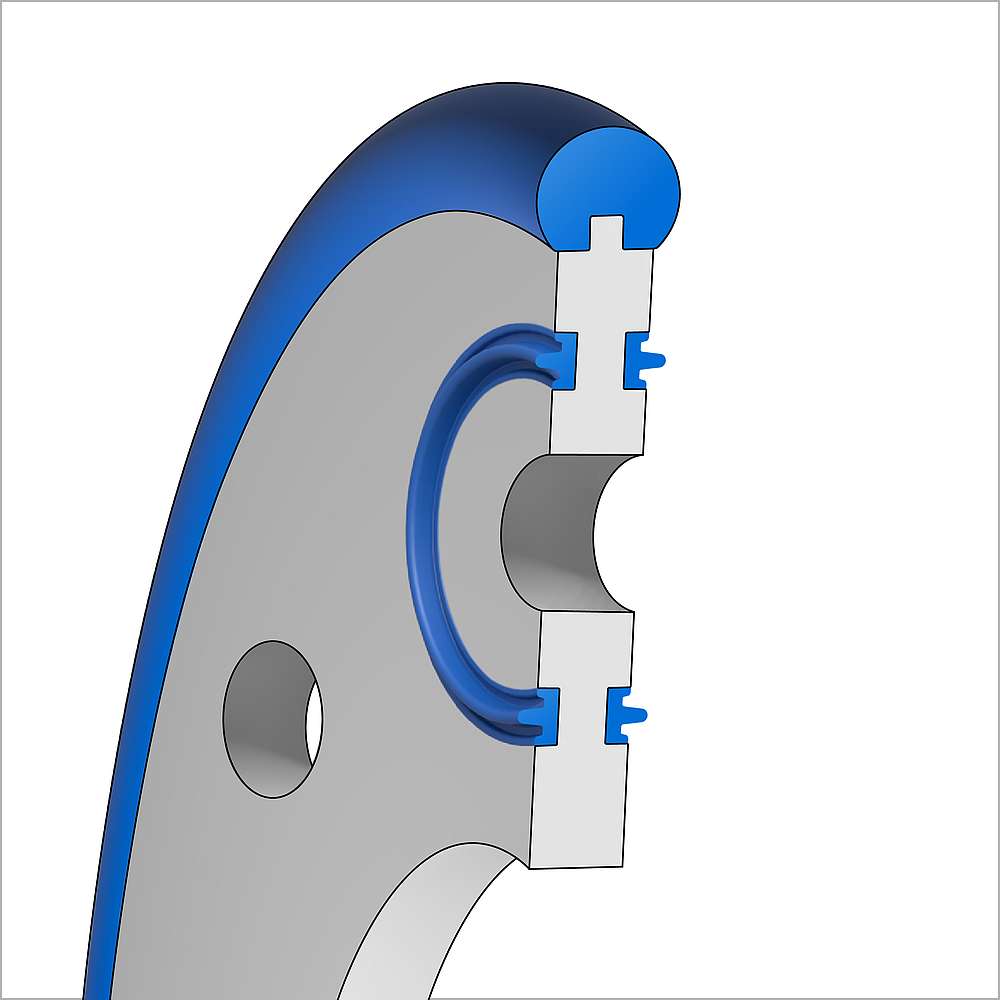

Versatile Performance

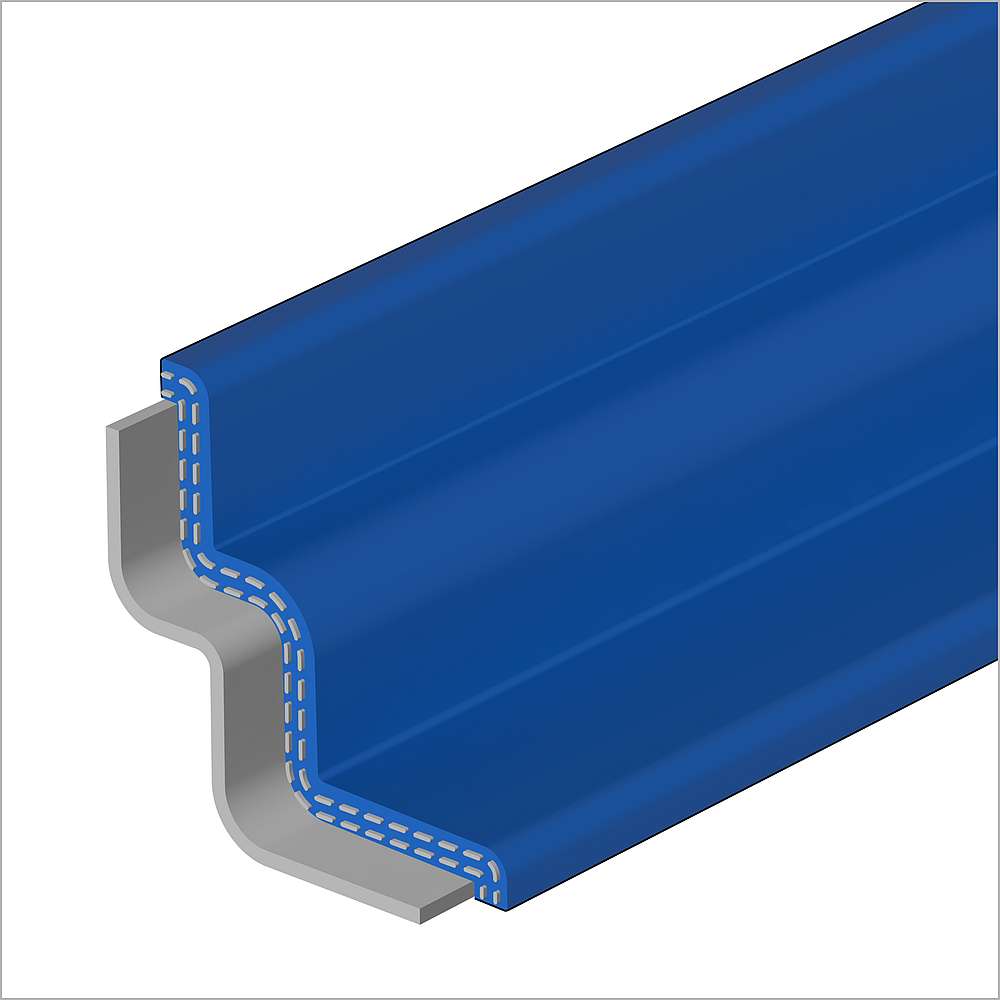

Our plate seals provide cost-effective versatility with specialized carrier and sealing materials, guaranteeing resilience in engine, fuel, and hydraulic systems against extreme temperatures and diverse media. Innovative designs streamline assembly, reduce costs, and offer an alternative sealing approach, optimizing efficiency.

Enhancing Airframe Integrity

Our innovative designs and materials provide comprehensive airframe sealing, ensuring coverage for cabin pressure zones such as doors, windows, hatches, and high-performance seals on flight control surfaces. With proprietary low-friction, abrasion-resistant, and low-density materials, we enhance our customers' efficiency and reliability goals, contributing actively to their objectives.

Resilience in Extreme Conditions

Our fire-resistant seals, crafted from proprietary elastomers and fabrics, endure 2,000°F / 1,100°C fires for 15 minutes according to AC 20-135 / ISO 2685 standards. With or without fabric reinforcement, our expertise ensures customers achieve test success on the first attempt, bolstering their trust in our capabilities amid extreme conditions.

Safeguarding Engine Components

Our proprietary materials provide robust protection for engine and nacelle components, shielding against extreme heat and fire. These thermal barriers seamlessly integrate with the substrate or function as blankets, utilizing elastomer, plastic, and/or composite constructions. Lightweight and cost-effective, they offer efficient customer safeguarding solutions.

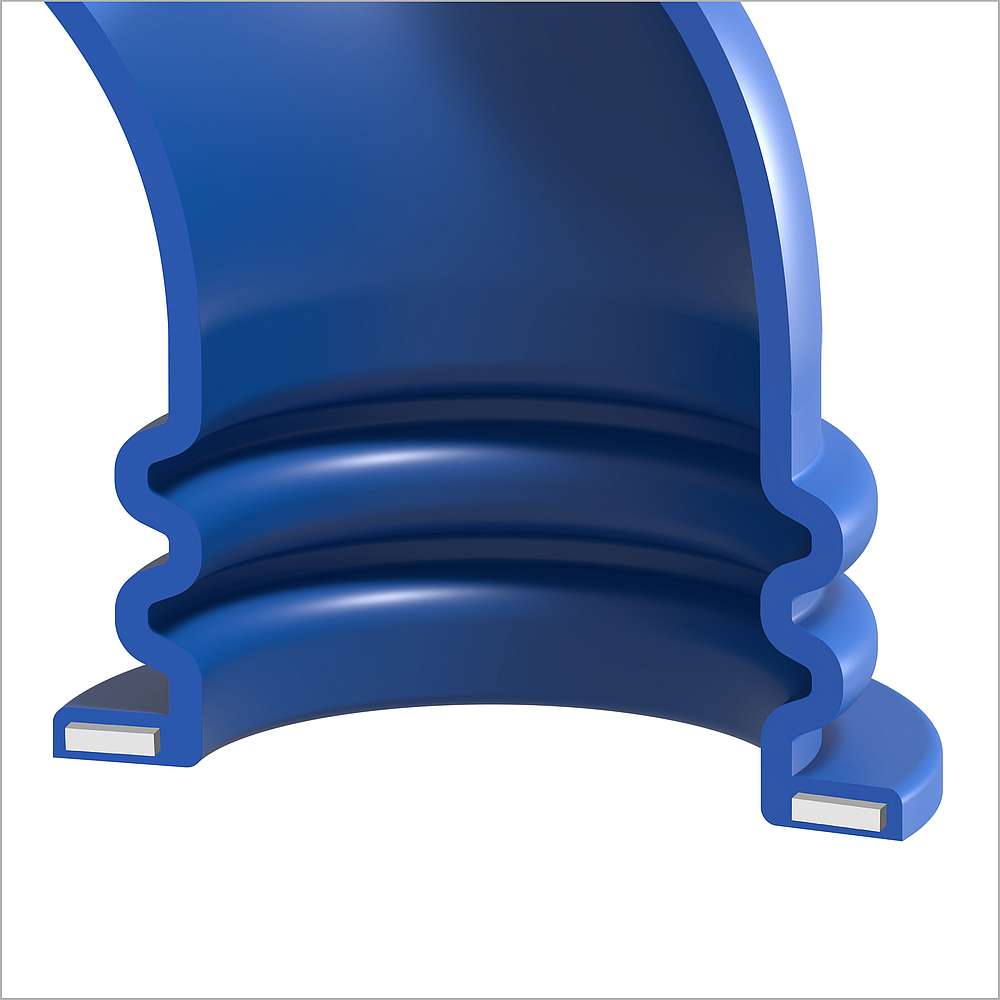

Flexible Fluid Transfer Solutions

Our elastomeric ducts, offering flexibility and lightweight construction, facilitate smooth liquid or gas transfer between rigid interfaces. Engineered for extensive movements and tolerances, they exhibit fatigue resistance. Utilizing proprietary materials, these ducts guarantee prolonged durability in extreme conditions and aggressive environments, with the option for added fire protection.

Tailored Protection Solutions

Our bespoke grommet designs guarantee exceptional protection for pass-through assemblies, securing wires, tubes, ignitors, connectors, and compressor vanes. These designs offer comprehensive defense against electrical, chafing, thermal, impact, and vibration risks. Moreover, they ensure effective gas/fluid sealing and, when necessary, fireproof capabilities, addressing diverse application requirements.

Strengthening Sealing Reliability

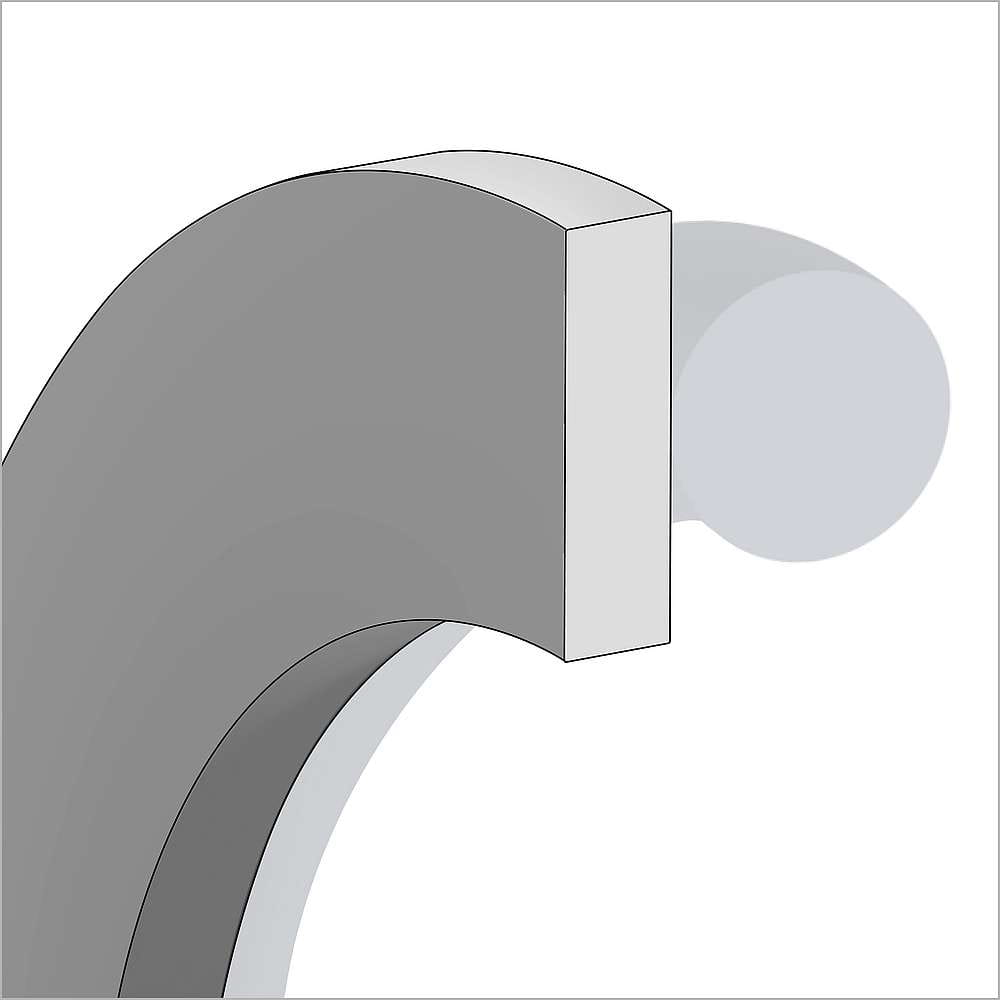

Our PTFE back-up rings elevate the sealing performance of O-rings and elastomer seals by averting extrusion. Available as solid, scarf cut, or spiral rings, these retainers harness our exclusive Quantum® materials, meeting AMS-3678 standards. They significantly extend seal lifespan, particularly in high-pressure and extreme temperature environments, ensuring heightened reliability.

Adaptable Sealing Solutions

Our silicone tape forms an airtight, watertight seal around electrical connections, bonding permanently within 24 hours. With no-adhesive technology, it allows easy, clean re-entry without substrate bonding. Additionally, it's available with fabric reinforcement, enhancing tear resistance and flame retardancy, ideal for applications requiring durability, such as hot air ducting.

Materials for Aerospace

Pioneering proprietary formulations, meticulously crafted in-house, exceed customer requirements.

Services for Aerospace

Aerospace News

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new