Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

FKM

FKM Rubber Material O-Ring Seals

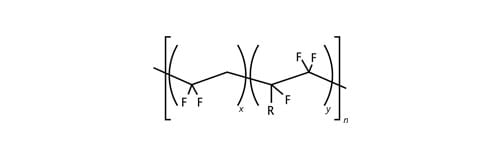

FKM is a copolymer made of highly fluorinated hydrocarbons and developed during the 1950s. FKM seals display very good resistance to media, ozone and aging. The material is also stable in fuels as well as petroleum-based oils and greases, along with aliphatic and aromatic hydrocarbons.

It is unstable with regard to polar solvents (e.g. acetone, MEK and ethyl acetate), low molecular weight organic acids (formic and acetic acid), glycol-based brake fluid, ammonia gas, amines, alkalis and superheated steam. There are copolymers, terpolymers and tetrapolymers with fluorine content varying between 65 and 71 percent. In this way, FKM can be precisely designed for specific requirements in terms of media resistance and cold flexibility. This is a benefit that, in particular, reliably protects applications in the chemical and pharmaceutical industries that have aggressive media and process temperatures of above 140 °C, which materials such as EPDM or HNBR cannot handle.

As a peroxide-crosslinked material, the newly developed 75 FKM 239961 from Freudenberg Sealing Technologies meets the latest regulatory requirements for materials in the food, beverage and pharmaceutical industries with direct product contact. Its very high purity, media and temperature resistance are also quite impressive, enabling it to be used as a static or dynamic seal in a wide range of applications. O-rings and diaphragms can now be manufactured from this material. In fact, customer-specific molded parts will also be possible in the future. Due to its clean structure, the material also fulfills all necessary certifications in the long term, such as EU (Reg.) 1935/2004, FDA § 177.2600, USP Chapter 87 (in vitro), USP Class VI Chapter 88 (currently in process), ADI free, BfR XXI (Cat. 4) and 3-A Sanitary Standards.

Fluoro rubber can be used from −25 °C to 200 °C and is predominantly used for seals in the automotive and commercial vehicle industry and in petroleum production, along with the chemical and aerospace sectors. Special types of FKM are even flexible at −40 °C. In general industry, FKM is used wherever there are high rotational speeds and high temperatures, for example, in radial shaft seal rings in pumps and transmissions.

Discover the new Technical Manual

Become a sealing expert! Our new edition offers an in-depth guide to materials and product expertise, offering a holistic view of sealing technology.

Read now!

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new