Product Modification

Product Modifications for Maximum Flexibility

As technology leader, Freudenberg Sealing Technologies offers numerous options for product modification - from adjustments of the sealing lip, to additional support rings, to the realization of your individual requirements. Our experts are at your side to provide you with advice and support.

Your Modification Options at a Glance

Modified spring

If an application generates an increased circumferential speed of the shaft, the elastomer material of the sealing edge and the lubricant may be subjected to high thermal stress, especially if the lubricant supply to the sealing point is insufficient. Depending on the technical conditions inside the unit, the friction and thus the temperature development can be significantly reduced by reducing the spring force resulting in a lower total radial force. This leads to a longer service life and energy efficient improvement in the system.

If there are high vibrations or there is a high radial runout of the shaft during operation, the spring force and thus also the total radial force generated can be increased in applications with limited circumferential speed. This improves the ability of the sealing lip to follow radial motions of the shaft.

If a rotary shaft seal is subject of a water or corrosive media ingress, it can cause corrosion, especially of the spring, if it is not made of a corrosion-resistant material (stainless steel). By replacing the standard spring with a stainless steel spring, the catalogue Simmerring® can be optimized to meet the specific requirements of the application.

Seal Type: Simmerrings, Radial Shaft Seals

Modification of dust lip

Simmerrings from the catalog program equipped with a dust lip offer optimal protection of the sealing lip against light external contamination by dust or splash water, while the dust lip is in contact with the shaft. At circumferential speeds of the shaft > 8 m/s, suction of the sealing lip and dust lip on the shaft surface occurs, generating increased friction, thermal stress and premature wear. Therefore, depending on the operating conditions, we recommend using seals with a dust lip in contact with the shaft up to a maximum circumferential speed of the shaft of 8 m/s.

If, in an application, the circumferential speed of the shaft is > 8 m/s and an external dirt load requires a design with a dust lip, a modified component with a vented dust lip can offset the suction of the lips towards the shaft and at the same time provide protection against external contamination.

The circumferential speed of the shaft > 15 m/s requires a modified catalog Simmerring® with a shortened dust lip without overlap to the shaft. Small clearance between the dust lip and the rotating shaft does not generate any additional friction. At the same time, the dust lip offers a certain degree of protection against larger contamination particles, despite its slight shortening.

Seal Type: Simmerrings, Radial Shaft Seals

Lubricated dust lip

Simmerrings with a dust lip which has an overlap to the shaft must be lubricated by using a grease pack that is applied before assembly. The amount of grease used is extremely important. Too little grease leads to lubrication of the dust lip for a limited time only. If too much grease is applied before assembly, the grease can be forced out of the grease chamber between the shaft and the dust lip when the temperature increases. The escaping medium can then be interpreted by the end customer as oil leakage. This so-called false leakage can be avoided by greasing the Simmerring® properly.

Seal Type: Simmerrings, Radial Shaft Seals

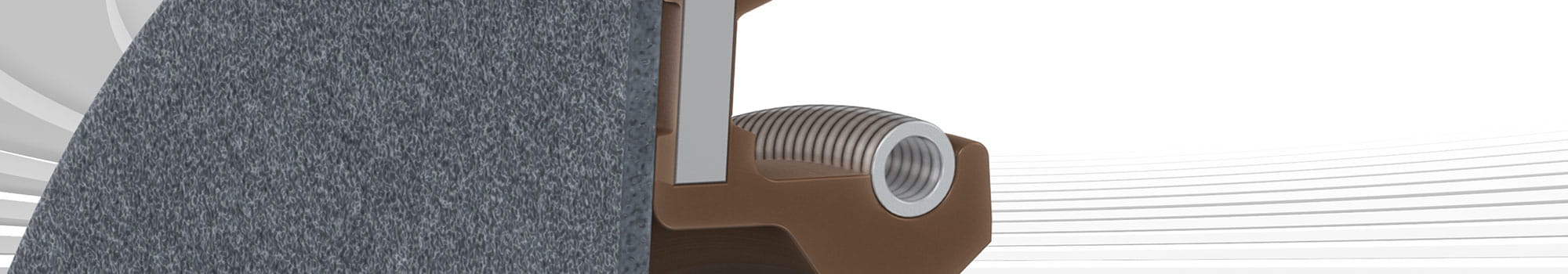

Modification with non-woven excluder lip

If there is a high contamination environment that exceeds the application limits of a conventional Simmerring® with a dust lip, a modified catalog component combined with a non-woven excluder lip from Freudenberg can be used. The non-woven materials being used can hold back dry dust and/or damp dirt. At the same time, however, the open-pored structure of the material prevents the non-woven excluder lip and the seal edge from being sucked on the shaft at high peripheral speed. The non-woven excluder lips also generate low friction with the shaft. The installation height is only slightly affected by the use of a non-woven excluder lip. This means that smaller heights can be achieved than with special designs or in conjunction with additional sealing elements.

Seal Type: Simmerrings, Radial Shaft Seals

Modification with electrically conductive non-woven washer eCon

Potential build-up between the shaft and the housing during operation can lead to voltage flashovers and, damage to the surface of bearing shells, for example. An electrically conductive non-woven washer provides equipotential bonding between the housing and the shaft and helps to increase the service life of the bearing and the overall system in critical applications. The installation height is only slightly affected by the use of the eCON. This means that significantly smaller installation heights can be achieved than with conventional equipotential bonding elements.

Seal Type: Simmerrings, Radial Shaft Seals

Modification with PTFE excluder lip

Contact with aggressive media can lead to chemical attack of the elastomer material. Particularly if systems need to be cleaned regularly, a PTFE excluder lip fitted onto the air side can protect the seal from contact with the aggressive cleaning media (CIP/ SIP). Solutions with food-grade PTFE materials are also available for food & beverage applications. The installation height is only slightly affected by the use of a PTFE excluder lip. This means that smaller heights can be achieved compared to conventional solutions in conjunction with additional sealing elements.

Seal Type: Simmerrings, Radial Shaft Seals

Simmerring® in combination with backup rings

Some applications require Simmerrings that can withstand pressure loads, such as the standard BABSL design. If no Simmerring® BABSL is available in desired sizes or if the pressure load is only applied for a short time, a BAUM profile without a dust lip that is supported by a backup ring can be used under certain operating conditions. As a rule, backup rings can be used up to a pressure of a maximum of 1-2 bar. This depends on the remaining operating conditions (temperature, speed, etc.), among other factors. The design of the backup ring must be adapted exactly to the sealing lip profile. For this purpose, you can request the corresponding drawing of the backup ring from us by simply providing us with the exact article designation or article number.

Seal Type: Simmerrings, Radial Shaft Seals

Download the overview of our modification possibilities as sales sheet.

Do You Have Questions About Product Modification?

Our experts will be happy to answer your questions personally.

Write us your request and we will call you back.