Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

16.11.2017 | Press release

Farm Equipment Another Application for Freudenberg’s Low-friction Sealing Solutions

Weinheim (Germany), November 16, 2017. ‘Green Future – Smart Technology’ – that is the central theme of AGRITECHNICA 2017, which takes place this week in Hanover. The world’s leading trade fair for agricultural technology is focusing on forward-looking products and technologies that enable a sustained increase in agricultural efficiency. In the agricultural industry as well as other sectors, Freudenberg Sealing Technologies provides low-friction sealing products that help to save fuel, reduce emissions and extend the lifespan of industrial powertrain systems.

Manufacturers of mobile work and heavy machinery for agriculture are facing the same challenges as automakers. Strict environmental regulations, rising fuel prices and long maintenance intervals require the use of new, innovative technologies. At the same time, sealing technology offers enormous potential. It is ultimately responsible for nearly one-quarter of all the lost mechanical energy in today’s automatic transmissions.

That’s why transmission manufacturers are working full steam to reduce system friction in transmissions, in order to keep performance losses as low as possible. Freudenberg is supporting them with its Low Emission Sealing Solutions (LESS) products, which reduce frictional losses, installation space, weight, fuel consumption and emissions. “Freudenberg Sealing Technologies has geared its research and development activities to the solution of these problems in particular,” said Angelika Mulac, Vice President of the Mobile Machinery business unit. “Innovative products such as Levitas and Levitorq are the result. The technologies were originally developed for our automotive customers, but we now use them for various product platforms and sectors, and ensure that all our customers benefit from highly advanced solutions of this kind.”

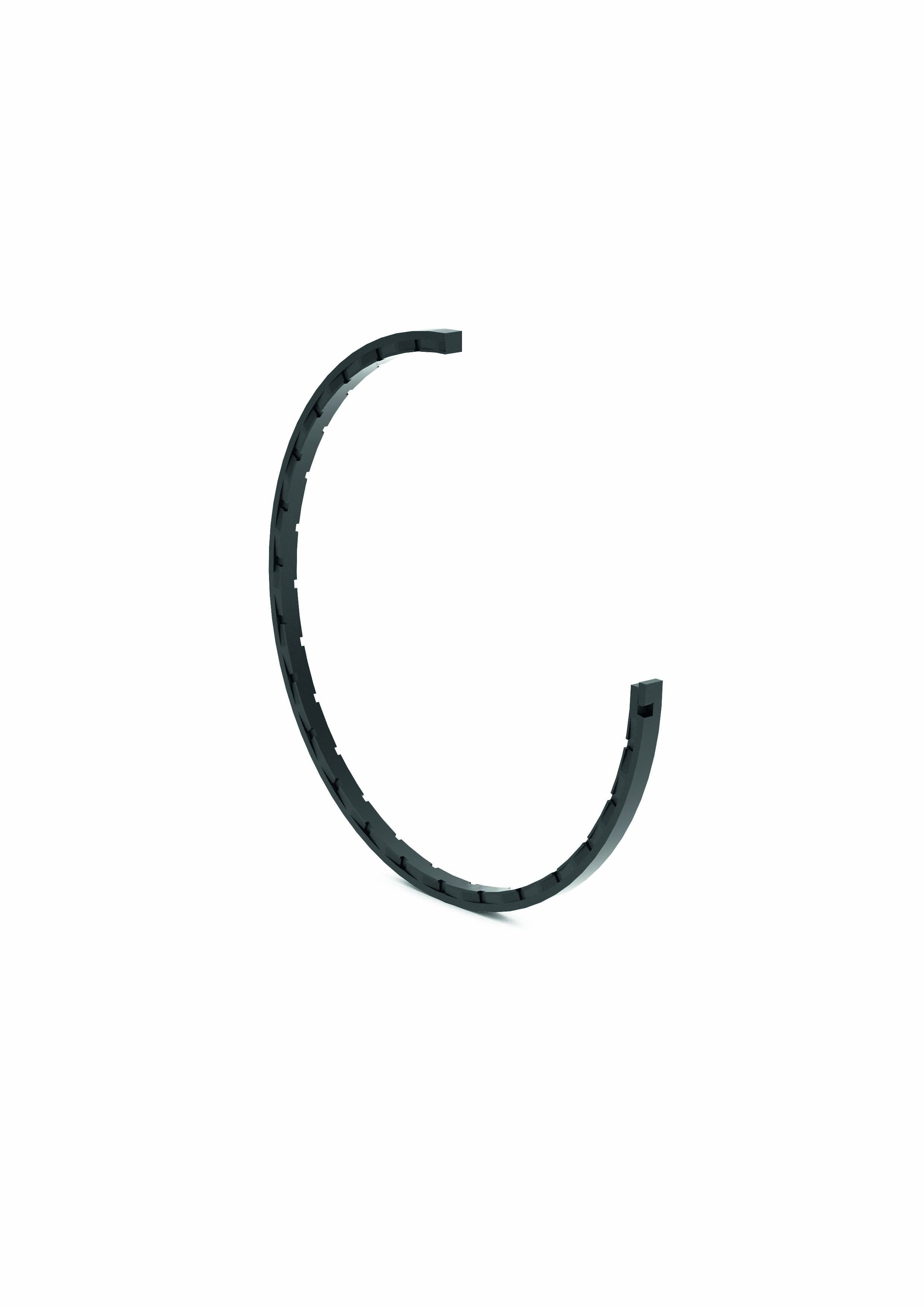

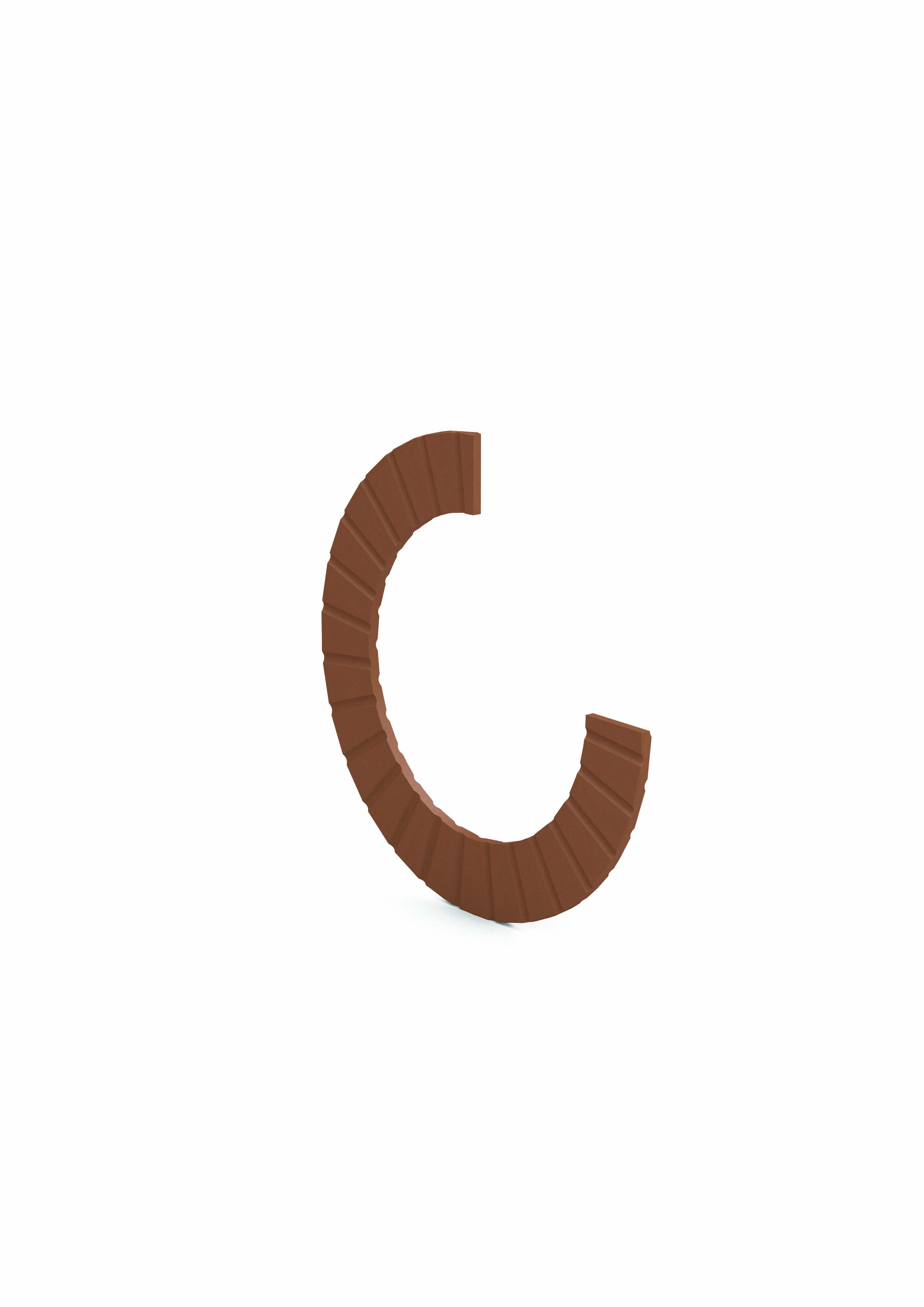

With the transmission seal Levitas, Freudenberg Sealing Technologies is pursuing a fundamentally new approach in seal design. During operation, the seal floats on a hydrodynamic oil film that it produces on its own. The film prevents direct physical contact between the shaft and the seal ring. As a result, only fluid friction occurs; this reduces friction up to 70 percent. Another advantage: The seals are bidirectional, which simplifies mounting at the transmission manufacturer.

Levitorq thrust washers from Freudenberg also function with a hydrodynamic oil film. They have been conceived in a way that allows a bearing to run or a force to act on its support surface. Thrust washers have been traditionally made of metal. Freudenberg has developed thermoplastic and thermosetting alternatives with the help of its material expertise and design know-how, in combination with special software programs and test capabilities. They are replacing heavy, torque-reducing thrust washers made of metal. This reduces the components’ weight and friction while improving flatness control.

More information on these products from Freudenberg Sealing Technologies for the agricultural industry can be found here.

Information on the company's LESS initiative is available at less.fst.com.

Press Release Downloads

Farm Equipment Another Application for Freudenberg’s Low-friction Sealing Solutions

Last update: 16.11.2017

English | DOCX | 86 KB

DownloadDownload Images

FST Angelika Mulac 2017

JPG | 770 KB

Download

FST bladder accumulator standing profile

JPG | 396 KB

Download

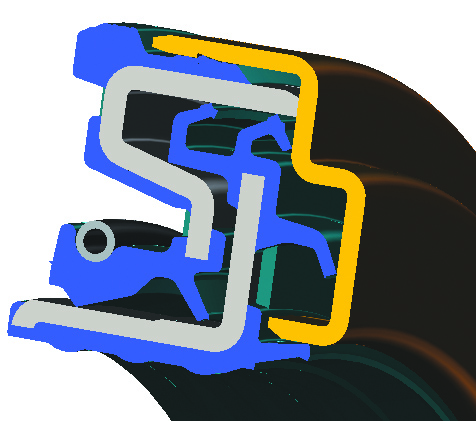

FST CASSETTE-S4 crosssection

JPG | 693 KB

Download

FST Cassette-S4 seal

JPG | 450 KB

Download

FST diaphragm accumulator standing profile

JPG | 2.08 MB

Download

FST Levitas standing profile

JPG | 2.04 MB

Download

FST Levitorq standing profile

JPG | 2.03 MB

Download

FST Piston accumulators lying profile

JPG | 2.06 MB

Download

FST Simmerring Cassette Com

JPG | 1.4 MB

DownloadUlrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.