Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

10.11.2017 | Press release

Freudenberg’s Innovative Seals Are Helping to Increase Agricultural Productivity

Weinheim (Germany), November 10, 2017. ‘Green Future — Smart Technology’ – that is the central theme of AGRITECHNICA 2017, which opens its doors Sunday in Hanover (Germany). The leading global trade fair for agricultural technology is focusing on forward-looking technologies and development trends that make sustained increases in agricultural productivity possible. That is exactly the mission of Freudenberg Sealing Technologies. Its sealing specialists offer a wide-ranging portfolio of innovative sealing technologies and suspension systems with diaphragm accumulators.

Agriculture is facing major challenges: The world’s population is growing steadily. Researchers expect the demand for food to double by 2050. But harvests and thus farmers’ income depend on the weather and political influences. As a result, they fluctuate. Meanwhile, the prices for agricultural products are at quite low levels. Yet the pressure on prices continues to be high in international competition.

“Dependability, longevity, efficiency and comfort are our customers' most important issues,” said Angelika Mulac, Vice President Mobile Machinery. “Our product and process solutions aim directly at them and are setting new standards in the industry. Thanks to our years of experience in material research, technology and product design, our components operate reliably even in the most demanding applications.”

Freudenberg Sealing Technologies’ sealing solutions for agriculture promote the best possible performance in all components of farm machinery. The appropriate special seals have been developed for axles, transmissions, engines and hydraulic systems. They include combination or cassette seals, premium pressure seals and multi-lip Simmerrings made of high-performing elastomers.

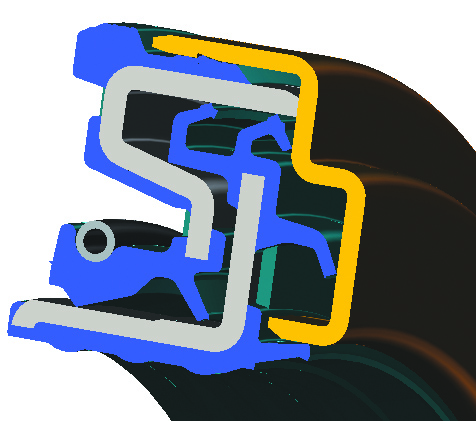

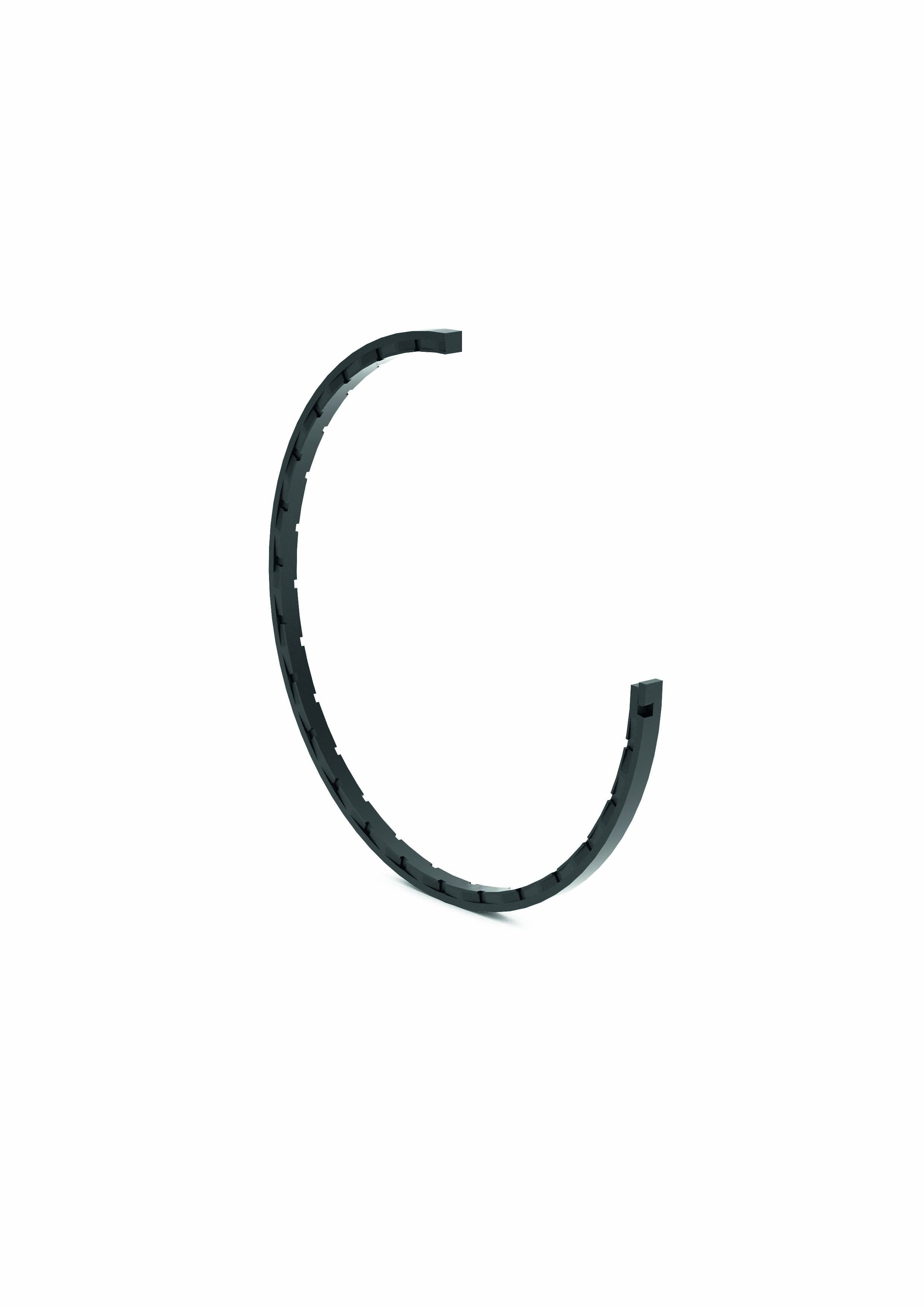

“Our solutions work dependably and with the greatest possible functional reliability. Especially during sowing and harvesting, downtime and breakdowns lead to reduced profitability. So the equipment must withstand long periods of operation, harsh environmental influences and contaminants without suffering damage,” Mulac said. Components from Freudenberg Sealing Technologies help companies meet these objectives. One example is the S4 cassette seal. Its innovative design keeps dirt away from the shaft while preventing the escape of lubricating oils or greases. Or consider a seal developed especially for use in tire pressure control systems. Marketed under the name ‘Central Tire Inflation Seal (CTI)’, it features two seal lips. So heavy agricultural machines can do their jobs on different soils, they increasingly have a system to vary the air pressure in tires. Until now, standard seals made from polytetrafluoroethylene (PTFE) were used for this. But they can leak at high pressures. The new patented solution from Freudenberg Sealing Technologies keeps transmission oil out of the line carrying the air to or from the tires. It can also improve tire traction by up to 20 percent while decreasing fuel consumption by 10 percent. The adjustment of the tire pressure also results in a 20 percent reduction in tire wear.

There are also extreme demands on components’ resistance to extreme temperatures. “The manufacturers don’t know whether a tractor will be used in the Arctic cold, or in the severe operating conditions of a rice field in Asia, with the axle immersed in water and mud, or on huge Australian acreages, where it must cope with the longest possible routes at high speeds,” Mulac said. “Our long-standing material expertise serves us well. Our patented material innovations made of elastomers, polyurethanes and polytetrafluoroethylene are continually expanding our products’ range of use. For example, our new polyurethane AU30000 can be used in temperatures ranging from -35°C to +120°C.”

With its innovative product solutions and components, Freudenberg Sealing Technologies is one of the auto industry’s established, global suppliers. Among other products, it has developed a special Low Emission Sealing Solutions (LESS) portfolio featuring innovative, low-friction, space- and weight-saving products, including innovative solutions for electric mobility. For example, the Levitas transmission seal and the thrust washer Levitorq float on a hydrodynamic oil film and thus cut friction and wear to a minimum. Engine seals such as the Freudenberg Casco seal and valve stem seals also increase engine efficiency. With these developments, Freudenberg is also helping its customers in the agricultural industry deal with current challenges such as tighter emissions limits. More information on this can be found here.

Press Release Downloads

Freudenberg’s Innovative Seals Are Helping to Increase Agricultural Productivity

Last update: 10.11.2017

English | DOCX | 87 KB

DownloadDownload Images

FST Angelika Mulac 2017

JPG | 770 KB

Download

FST bladder accumulator standing profile

JPG | 396 KB

Download

FST CASSETTE-S4 crosssection

JPG | 693 KB

Download

FST Cassette-S4 seal

JPG | 450 KB

Download

FST diaphragm accumulator standing profile

JPG | 2.08 MB

Download

FST Levitas standing profile

JPG | 2.04 MB

Download

FST Levitorq standing profile

JPG | 2.03 MB

Download

FST Piston accumulators lying profile

JPG | 2.06 MB

Download

FST Simmerring Cassette Com

JPG | 1.4 MB

DownloadUlrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightNews Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightMore news on the subject Technology & Innovation

First Hand News

Best of all, keep up with the latest developments

with the Freudenberg Sealing Technologies newsletter.