Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

04.09.2024

Boosting Battery Cycle Life

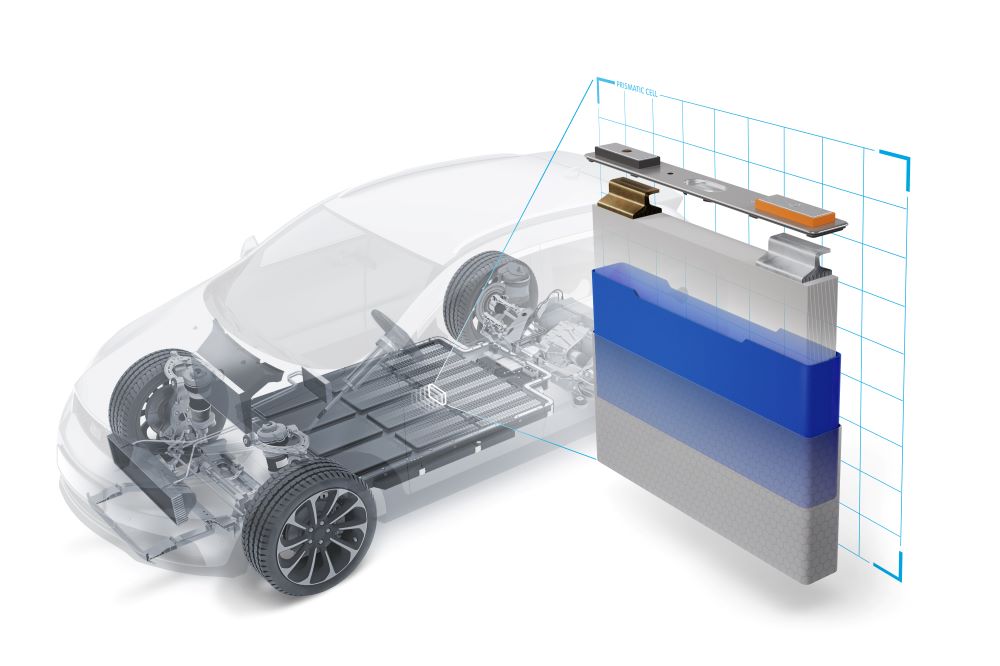

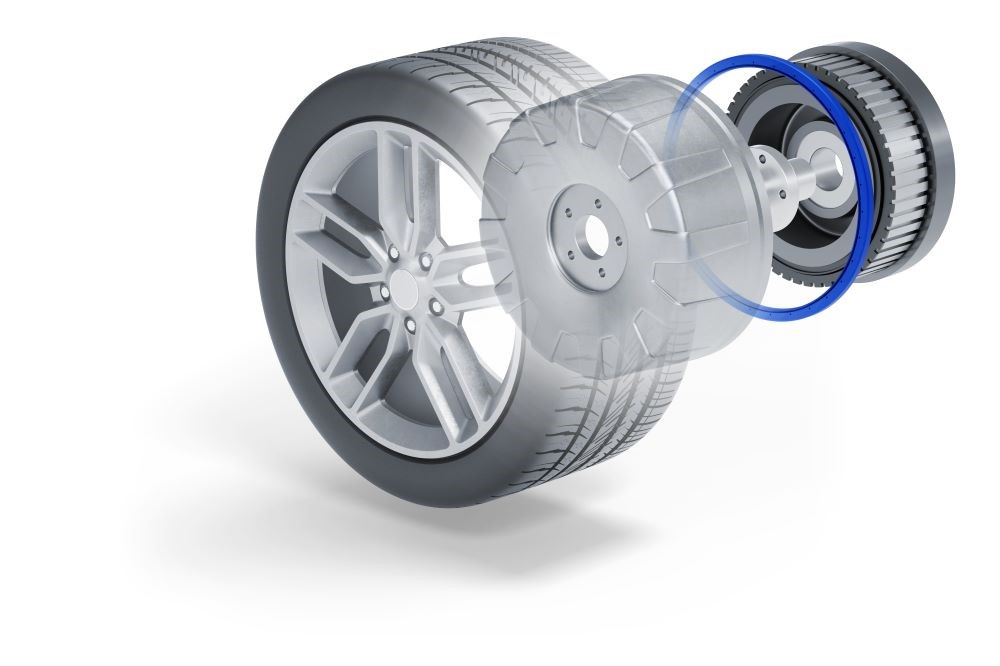

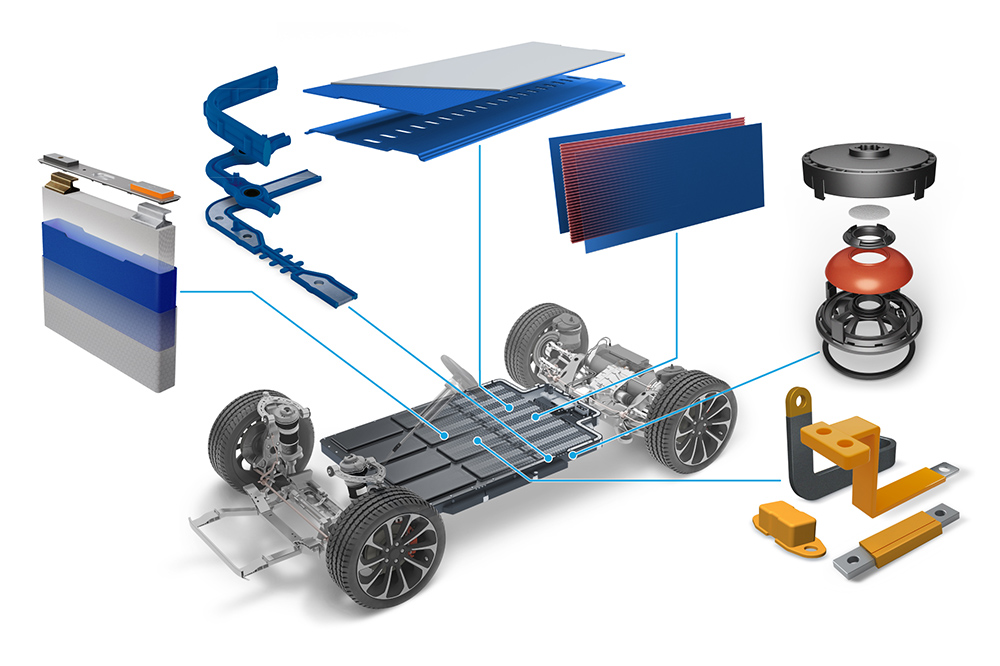

By 2030, well over 100 million electric cars are expected to be on the roads worldwide. To make electromobility more efficient in the future, nearly all manufacturers are working to increase range and reduce charging times. High-performance batteries are one of the priorities in this development. Freudenberg Sealing Technologies assists manufacturers by providing innovative solutions that increase cell reliability – solutions that contribute to a longer cycle life, greater design flexibility and advances in cell design. With its cell caps and cell envelopes, Freudenberg Sealing Technologies now has two products ready for series production.

Nonwoven cell envelopes advance new cell designs

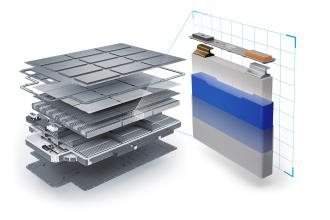

Battery cell envelopes from Freudenberg Sealing Technologies consist of innovative nonwoven materials that wrap the cell stack and – just like conventional films – protect it during the assembly and provide the necessary electrical insulation. In addition, the nonwoven materials offer significant technical advantages over standard films used in this application today.

Nonwoven envelopes consist of fiber network forming an ultra-homogeneous pore structure. The fibers are surface treated for permanent electrolyte wettability. This results in a lower risk of entrapping gas bubbles as the cell is filled and helps to keep the cell stack wetted over the lifetime.

Compared to conventional foils, nonwoven materials filled with electrolyte also lead to an improved heat management within the cell – due to the resulting higher thermal conductivity. Similar to a sponge, the absorbed electrolyte in the nonwoven creates an additional electrolyte reservoir in the cell. The electrolyte is released when the nonwoven is compressed, which happens during the aging of the cell when the stack swells – just exactly when additional electrolyte is needed.

When acting as an in-cell compression element, thicker layers of nonwoven envelopes can absorb a large portion of the cell stack growth within the cell, allowing thinner compression elements between single cells. In addition, absorbing cell stack growth inside the cell results in a more even load distribution on the cell stack itself– therefore reducing the risk of dendrite formation and Lithium-plating.

All these additional functions contribute to a longer cycle life and help to resolve a big challenge in battery technology.

Cell caps ensure long battery life

To boost the safety and performance of electric vehicles, Freudenberg Sealing Technologies offers custom-designed cell caps, developed in collaboration with cell manufacturers. All necessary functions are integrated, including rupture disks that dissipate escaping gases in case of a thermal runaway of the cell. These are manufactured on site for the local market with the lowest possible carbon footprint and in accordance with automotive standards such as IATF 16949.

“In these customer projects, we combine state-of-the-art materials with intelligent design and merge our expertise in sealing technology and engineering plastics with our knowledge of stamping technology. This allows us to set new standards to ensure perfect sealing and a long cycle life for the cell caps,” says Giulia Richard, Global Marketing Director at Freudenberg Sealing Technologies.

Cell caps that are welded to the inner electrodes effectively seal and insulate the battery cells. Freudenberg Sealing Technologies’ cell caps are tested to be absolutely gas-tight and maintain this capacity throughout the cycle life of the battery. This ensures optimum performance under a wide range of operating conditions, minimizes the risk of gas leakage and increases safety. In addition, the cell caps have exceptional mechanical resistance to peak loads and fatigue. Their compatibility with various electrolytes, any coolants from outside and gases enables seamless integration into different electric vehicle systems. All materials used have been electrochemically tested.

“Mobility is changing, and Freudenberg Sealing Technologies is staying ahead of the curve. As the market leader in the technology, quality and service segments for the automotive sector, we have all the expertise necessary to develop and manufacture innovative and leading-edge products for the mobility of the future,” emphasizes Ulrich Huth, President Automotive Sales at Freudenberg Sealing Technologies.

Ulrike Reich

Head of Media Relations & Internal Communications

Telephone: + 49 (0) 6201 960 5713

ulrike.reich@fst.com chevron_rightDownload Press Release

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now! chevron_rightFurther Articles With These Taggings

News Service

You can subscribe to the Freudenberg Sealing Technologies news alert service, bringing you the news as soon as they are published. You can always unsubscribe from this service.

Subscribe now!