Obtain news and background information about sealing technology, get in touch with innovative products – subscribe to the free e-mail newsletter.

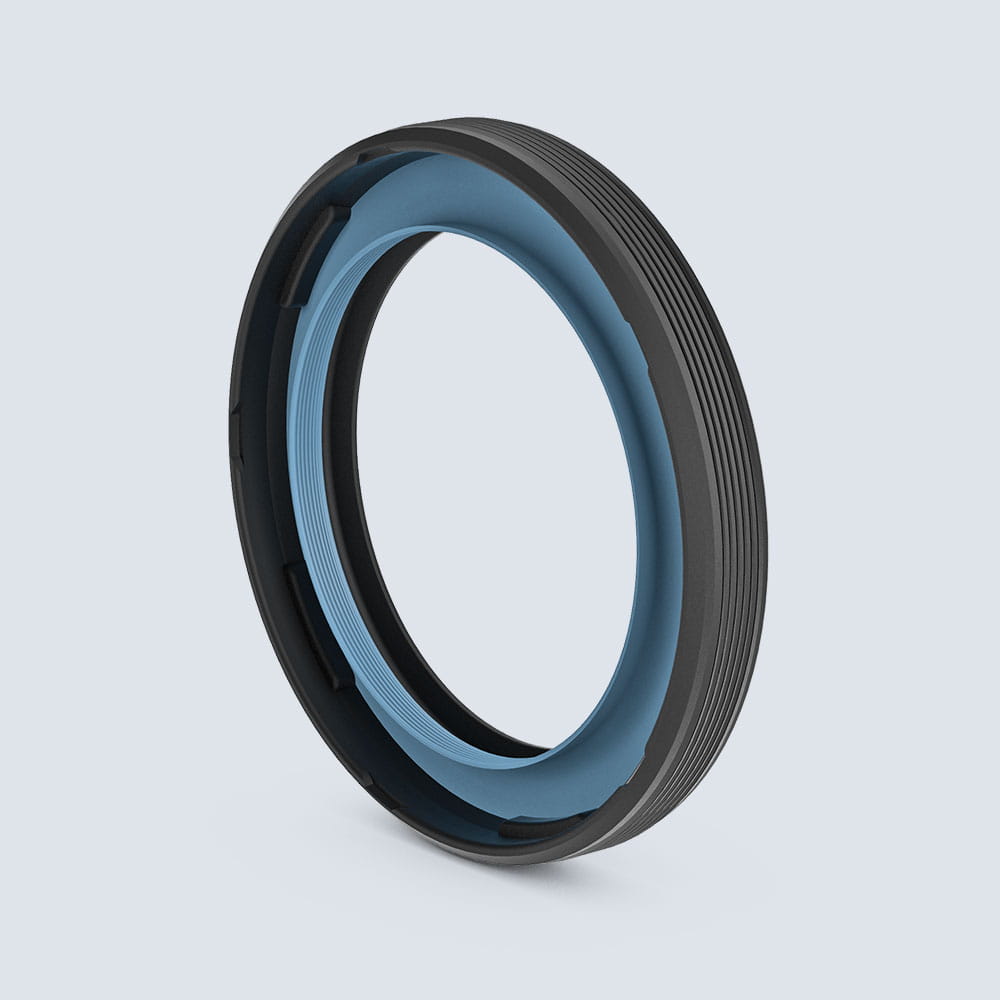

Radial Shaft Seals

Radial Shaft Seals, Rotary Lip Seals also known as - The Simmerring®

The Original and Its Innovative Advances

Simmerrings seal rotating shafts reliably and are used in millions of applications and a variety of equipment in general industry and the automotive sector. This radial shaft seal ring is based on know-how gained from years of experience. It continually undergoes further refinement based on the latest technological developments, and is particularly functionally reliable, flexible and extremely stressable.

Contact usAlways “Up-To-Date”

The tried-and-tested original Simmerring® keeps up with the times. Our experts have continued to develop it, for example, with improvements in seal lip profiles. This has made it possible to further improve its reliability and functionality across a broad range of applications. The improvements include a friction-optimized design to decrease fuel consumption, which leads to reductions in CO2 emissions.

Freudenberg Sealing Technologies offers a comprehensive selection of products suited to a variety of requirements. The range is further expanded by creating combinations with other components and additional functions.

Elevate Your Radial Shaft Sealing Systems with Precision Engineering

Discover precision engineering with Freudenberg Sealing Technologies. Our specialized Simmerring® engineering services go beyond selecting top-tier components. We analyze everything to unlock optimal sealing performance. Trust our expertise and commitment to excellence in sealing systems. Harness precision and innovation for peak performance.

Simmerrings Must Be Adapted to Varying Operating Conditions to Achieve Friction-Free Operation:

- Diameter and rotational speed of the shaft

- Temperature

- Pressure

- Dirt accumulation from outside

- Dirt accumulation in the assembly to be sealed

- Media to be sealed off (lubricating oil or grease, other liquids, paste-like or gaseous media)

The Professional Solution for Your Task

Our selection includes Simmerrings adapted to all these parameters and different ranges of use. You can find more information about them in our product catalog.

The Advantage:

-

Long operating life: This increases the operational efficiency of your facilities and equipment, along with the security of the investment.

-

High functional reliability: The Simmerring® minimizes downtime and ensures reliable operation.

-

Easy mounting: Simmerrings can be mounted quickly. This saves time and reduces costs.

Our Products in Detail

Premium Sine Seal (PSS)

Thanks to its unique design and sealing behavior, the Premium Sine Seal from Freudenberg Sealing Technologies can more than double the service life of the sealing system. Our new sealing solution seals reliably, reduces friction and power loss, and actively counteracts internal contamination in the sealing system.

Gerromatic

For the development of the innovative Gerromatic G 61 our engineers have taken nature as a role model. The special design of the sealing lip distributes the pressure, so that a wider contact zone for the fluid film between the shaft and sealing lip is used. The benefits for the process industry are better friction, less wear and a low heat generation, which extends the lifetime of the seal.

Sealing Modules

As integrated solutions, Sealing Modules have the advantage of using fewer components, offering easier installation, reducing weight and saving space.

Blue Seal

The BlueSeal design and its low friction PTFE POP® lip are based on long experience with the PTFE Simmerring®. The weight savings of 40% and an installation space reduced by 50% support future requirements for emissions reductions.

CMS

The Contact Minimized Simmerring® (CMS) delivers greater durability with less friction for the small shaft diameters, 5-20 mm, typically found in sensor, actuator, pump and throttle applications.

ESS

The Energy Saving Seal® (ESS) minimizes friction on the crankshaft and camshaft and in transmissions. This significantly reduces fuel consumption and emissions. The reduction of friction also extends the seal’s operating life while increasing the machine’s reliability.

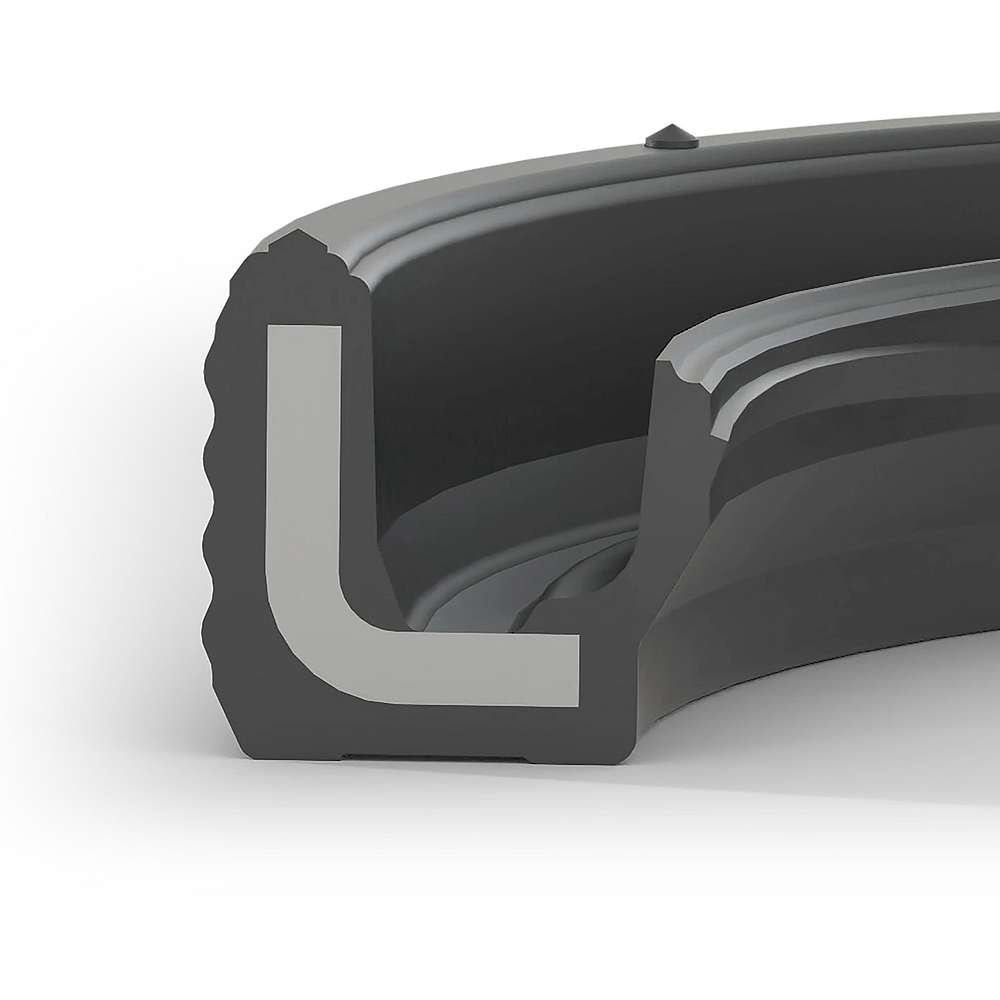

Cassette Seals

Cassette Seals consist of a Simmerring® and an optimized wear sleeve (either hard or soft unitized). They are used to seal shafts in heavy construction and agricultural equipment that, for example, are exposed to high stresses. They also effectively protect engines, transmissions, differentials and axles against dirt, water and other environmental influences. The latest developments in elastomers also make it possible to achieve optimal sealing without a spring. This reduces friction even at high temperatures. Combi seals consist of a Simmerring® (individual or double lip) and a polyurethane wiper. They increase the protection against external contaminants while allowing axial and rotary movement.

Combi seals

Combi seals consist of a Simmerring® (individual or double lip) and a polyurethane wiper. They increase the protection against external contaminants while allowing axial and rotary movement.

LFS

The low-friction Simmerring® (LFS) is a combination of advanced, high-performance and friction-optimized ACM materials.

Lube & Seal

The customer benefits all around when – and only when – the seal and the lubricant work in perfect harmony – with friction-free processes, cost-effective systems, and market-driven solutions. Based on this insight, Freudenberg Sealing Technologies and the Freudenberg Group’s Klüber Lubrication have bundled their ground-breaking know-how to create Lube & Seal, an innovative sealing system from a single source.

PTFE POP®

The PTFE POP® seal (= Power Optimized PTFE) demonstrates its robustness as a PTFE Simmerring® by adjusting material and geometric characteristics for minimal friction.

Simmerring & Encoder

The combination of a Simmerring® with an integrated encoder not only seals the shaft reliably but captures its rotational speed as well. The collected data are fed into the engine control unit, allowing the optimization of the combustion process. The result: less fuel consumption and lower emissions. Other advantages include a reduction in the number of components and in the size of the installation space, along with easier mounting and a decrease in weight.

Related Products of the Dichtomatik Brand

Premium Freudenberg brand products meet the highest quality requirements and are suitable for all segments and applications. Complementing this, Dichtomatik brand products are a good solution for moderately demanding, non-safety-critical applications.

Dichtomatik Radial Shaft Seals open_in_new

Gearbox Innovations

Dive into this captivating on-demand webinar and explore the revolutionary world of Simmerring® seals.

Watch webinarRelated Topics

Join Us!

Experience Freudenberg Sealing Technologies, its products and service offerings in text and videos, network with colleagues and stakeholders, and make valuable business contacts.

Connect on LinkedIn! open_in_new